How the Textile Industry Came to Be

Nov 1st 2022

The textile industry is one of the oldest yet fastest-growing industries in the world; after all, clothing is one of the primary commodities that every person on Earth needs to own. Textile manufacturers do a very good job today producing high quality materials from both synthetic and natural fibers that are offered to the general public. Textile producers, however, did not have an easy trail to follow leading to their success.

It's history

While a lot of struggling people were immigrating to America to start a new life, a small group of these people stood at the forefront and led America through its Industrial Revolution. This group of textile entrepreneurs invented power-driven machinery and developed business enterprises to produce products that had previously been made in low volume in homes and small shops, leading to a factory boom.

The industrialization of textile manufacturing began in the late 1700s in Great Britain when Richard Arkwright invented the “spinning frame” that could turn raw cotton into a mass produced yarn.

An early Spinning Frame However, it wasn't until 1790 that the industry began to spread widely to the United States. This movement can largely be credited to an English-born businessman named Samuel Slater. At the age of 21, Slater had worked in a textile factory for six years and had learned the mechanical details of Arkwright’s machine. He carried this knowledge with him as he ventured out of his country and onto the American shores, confident that he could reinvent the spinning frame and make a fortune for himself.

When he arrived in Providence, Rhode Island, he formed a partnership with the textile-manufacturing firm of Almy & Brown. Slater built the spinning frame based on the Arkwright model just from the details he had memorized. Its first use was on December 20, 1790 in Pawtucket, Rhode Island, where the waters of the Blackstone River turned the wheels of the mill. The success of Slater’s mill revolutionized the textile industry in America, which up to that point was dependent on cottage workers to produce yarn and thread.

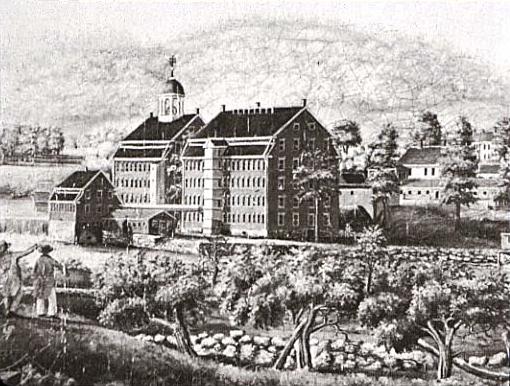

Slater Mill Pawtucket, Rhode Island Because of this innovation, factories in the US began to multiply rapidly, earning Slater the title of "The Father of the American Factory System" as well as "The Father of the American Industrial Revolution.” By 1815, there were already 165 cotton mills operating in New England. These early mills were not large-scale, so New England merchants continued to utilize home workers to weave some of the yarn into cloth for some time after Slater’s innovation.

This video shows an early spinning frame in action at the Slater Mill.

The spawning of other products

The beginning of the 18th century marked the production of textiles made with wool from sheep farms across the midlands in Britain. More than a quarter of the British exports during that time were from the export trade in woolen goods, doubling between 1701 and 1770. Another textile industry that invested in cotton centered in Lancashire showed remarkable growth during that time, although it did not equal the huge value of the woolen trade. Before the start of the 17th century, only individual workers manufactured a somewhat limited number of goods, which were distributed around the country.

In the early 18th century, artisans started to find alternative materials to produce products. They were using silk, wool, fustian, and linen, but all were eventually overcome by cotton, which became the most important textile of the time.

Cotton was first imported into northern Europe in the late medieval period. At the time people did not have any knowledge of where it came from. They associated the material with wool, noting their similarities, they conceptualized that plant-borne sheep must produce it. It was later called “tree wool.” Even Christopher Columbus in his explorations of the Bahamas and Cuba in the late 1400’s, found natives wearing cotton garments. During the late 16th century, cotton became more and more popular as it was cultivated in the warmer regions of Asia and America.

The production of cloth involves not only the growing and harvesting of the fiber or raw material, but the product must then be prepared and spun into thread or yarn, and finally weaving the yarn into cloth. Thereafter, the cloth will be taken to the garment manufacturer. Preparation of fiber will depend on the fiber used, but it can involve retting and dressing. Wool needs to be carded and washed. Spinning and weaving can be similarly done to fibers, as well. Spinning is done by twisting the fibers by hand using a drop spindle or a spinning wheel.

The industry’s forerunners

Eli Whitney invented the modern mechanical cotton gin, which quickly separates the cotton fibers from their seeds, in 1793.

Cotton Gin on Display the Eli Whitney Museum

Here is a brief video history of Eli Whitney and his impact on the textile world:

It was in 1813 that the New England factory systems started to take off when Frances Cabot Lowell, Nathan Appleton, and Patrick Johnson established the Boston Manufacturing Company and opened their first factory, wherein workers operated spinning and weaving machinery. This enabled the home-based workers to shift their jobs from their homes to the factories. Fifteen years later, the company started adding branches throughout Massachusetts and New Hampshire. By 1840, the Boston Manufacturing Company had gained a great deal of popularity, as others tried to copy their corporate model.

Boston Manufacturing Company on the Charles River, Waltham, Massachusetts Lowell and his team hoped to change the ways of the British industry. Building their facilities in Massachusetts, he hired young and unwed women from the farms of New England. Known as the “mill girls”, they were strictly chaperoned by matrons who established curfews and a stringent moral code for the girls to follow. The mill girls worked 12 hours per day, 6 days per week. Although it was a tedious job, most of the girls enjoyed the independence the mill gave them, in contrast to how they had lived on the farm. Moreover, the wages rose to triple the rate for a domestic servant at the time.

It was also during this time when leaders such as William Gregg of South Carolina established a home-based textile industry, which was resisted by the northern mills. After the Civil War, the south slowly replaced the use of slaves with regular workers. Edwin Michael Holt and his family in North Carolina built a number of mills all over the south at the end of the 19th century, including Glencoe Cotton Mill and mill village, which are still preserved to this day.

Later on, merchants such as the Marshall Fields of Chicago acquired and built mills of their own (Cone Mills and Fieldcrest Mills) so as to better control and regulate the supply.

As World War I took place, several new companies emerged to satisfy the war demand. After the war, imported machinery from Germany and Switzerland started to replace domestic supply.

During the late 19th century, the Made in the USA began to be replaced by a new world order. Because many textile manufacturers aimed to buy from the producers with the lowest cost, most textile companies considered importing from other countries.

Today’s industry

As the 20th century approached, major changes came to the textile industry as innovations allowed textile machinery to create synthetic fiber such as rayon and nylon, which is used in products ranging from pantyhose to toothbrushes.

Acetate was invented in the 1920s. A decade later, polyester and acrylic were introduced. Polyester became more popular in the Unites States than cotton for some time during that century.

By the early 20th century, globalization also led to the outsourcing of textile manufacturing to overseas markets. This created a trend of focusing on white-collar industries for fashion design and retail.

An apparel distributor, Outlet Shirts, specializes itself in the screen-printing and embroidery industry as well as blank apparel. It provides well over 1500 products from brands such as Port Authority Apparel, Port and Company, Eddie Bauer, Nike Golf, Sport-Tek and more. Offering a large selection of wholesale t-shirts, polo shirts, woven, outerwear, ladies styles and many more. Its products are available either blank or embellished with your company or group logo. Its low prices and generous discounts, also includes free shipping starting at $125, will make it easy for any customer to save more without sacrificing quality or service.

The textile industry has come a long way from just old-fashioned machines and factories. It has developed greatly over time, paving the way for companies who produce quality products for their customers. Today, it has become a very essential industry the world could not live without.